Copper ore comes from copper mine, which can become high grade concentrate copper or copper sand. Concentrate copper ore can be refined copper and copper products by smelting Commission. Copper ore species mainly contain natural copper, chalcopyrite, bornite, chalcocite, covellite, and azurite. They are mainly applied in the field of copper ore smelting industry as the raw material of copper industry.

THE PRODUCTION PROCESS OF COPPER ORE PROCESSING

The production process of copper ore mainly include: crushing, grinding, ore dressing. In the crushing process, three crushing circuits are suitable for high hardness iron ore broken, which can complete the ore crushing and partial dissociation work so as to improve the efficiency of the subsequent grinding. In grinding process, two sections of a closed grinding is efficient grinding process, which can make the copper mill more fully. In the new process, the representatives of emergence successful processing technology in recent years are: “stage grinding, low intensity magnetic separation and reverse flotation technology”, “magnetic separation”, “ultra-fine crushing wet magnetic separation tailing process”

First stage:Large copper stones in bin are sent to jaw crusher or mobile jaw crusher station (early break) by vibrating feeder to be crushed evenly.

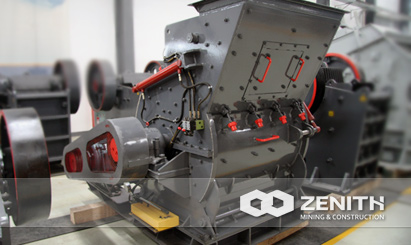

Coarse crushed ore are sent to the single cylinder hydraulic cone crusher (two break) by belt conveyor after sieving shaker to be broken;

Copper ore materials after medium crushing are sent into multi cylinder hydraulic cone crusher to be fine crushed.

In this stage, vibrating feeder, PE series European version jaw crusher, CS series multi-cylinder hydraulic cone crusher and vibrating screen are necessary.

Second stage:After sieving shaker, 0-12mm powder evenly enter into the ball mill to grinding and sieving and are classified by the spiral classifier. Unqualified copper powder will be sent to the ball mill to mill again. In this stage, ball mill and spiral classifier are indispensable.

Third stage:The qualified copper powder is sent into the flotation machine to mix flotation. In this stage,spiral chute and flotation is necessary.

Forth stage:The resulting powder enters into the dryer to be concentrated copper powder. The last stage need machine is dryer.